Mark Weaver, newly married at age 18 and a full-time college student, manufacturing hot rods and equipment trailers in his 26’ x 32’ garage on Spokane’s north side.

While working 40-plus hours a week as a boilermaker for the Great Northern Railroad, Mark gets serious about his side business, calling his new venture “Metals Fabrication Company.”

Mark moves to a 1,200 SF shop east of downtown Spokane and focuses his Spartan trailer line, which includes beavertail, tilt-deck, and hoist models.

On October 1, Mark goes all-in on Metals Fabrication Co., quitting his job at the railroad and adding 2,000 SF of shop space.

Metals Fab enters the structural steel business.

The company moves back to north Spokane to a 4,000 SF shop on half acre on East Holyoke.

The shop expands yet again – adding 800 SF – and drops its trailer line to focus entirely on structural steel and miscellaneous metals.

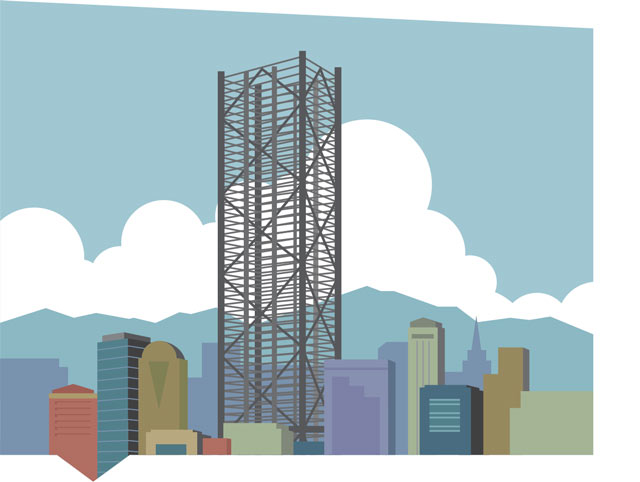

Metals Fab begins winning larger structural projects outside the Inland Empire.

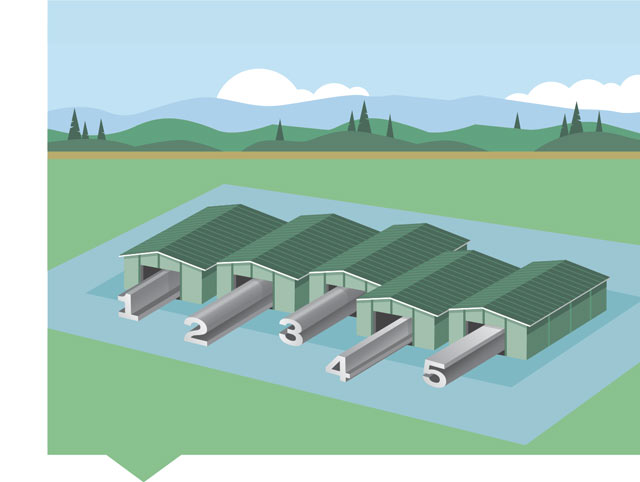

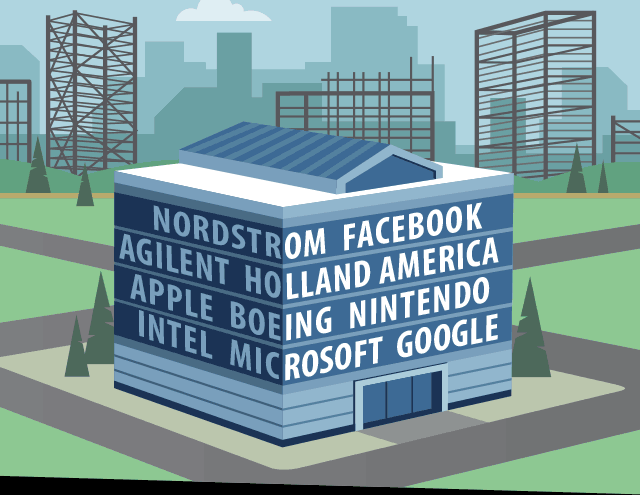

The company moves to its present location in Airway Heights which, at the time, comprises 100,000 SF of shop and office space on 14 acres. Nobody at Metals Fab believes they’ll ever use it all.

Metals Fab achieves AISC Quality certification.

Mark Weaver retires, selling the company he built to his children Sara (with Metals Fab since 1996) and Todd (1989), long-time employee Tim Mathison (who started in 1977), and Mark’s brother Dan (1986).

Another expansion: Bay 1 and 6 additional acres.

Dan Weaver retires and sells his share of the company to Todd, Sara, and Tim.

An eventful year: Metals Fab achieves AISC Bridge certification, participates in Steel Day for the first time, and is featured in Modern Steel Construction.

In order to focus more on his family and on training for Ironman competitions – of which he eventually completes three – Tim Mathison sells his share of Metals Fab to Todd and Sara and reduces his work load to part-time.

The addition of a new Controlled Automation Revolution plasma coper greatly speeds up beam processing.

On August 26, Tim Mathison, who joined Metals Fab at age 18 and worked there for 37 years, succumbs to lung cancer after a two-year battle.

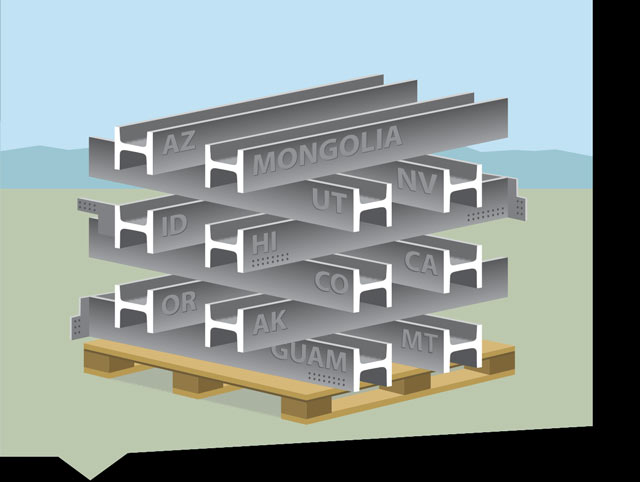

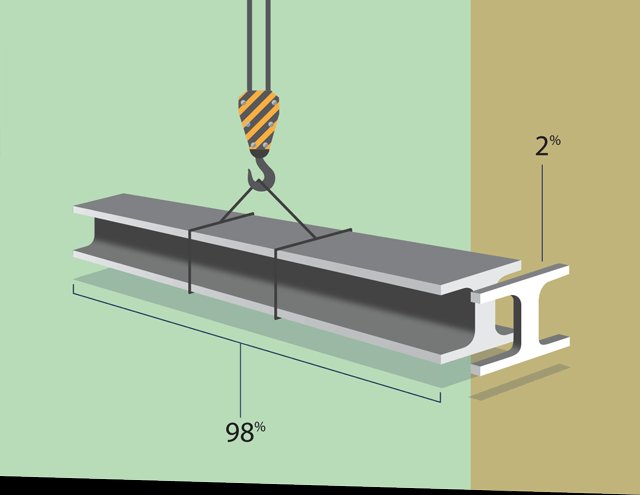

Sara and Todd purchase three additional acres for inbound steel storage, while the addition of a new high-speed mitre saw and drill line improves heavy and deep section beam and column processing.

Metals Fabrication Company celebrates 50 years in business.